Power D+

The most powerful Axis controller with PLC and HMI integrated

The Power D+ based on a high level RISC processor at 264 Mhz that can be coupled to a non-volatile RAM with high speed and parallelism. The Motion Control section, which manages up to 24 interpolated axes, uses a Look Ahead function to pre-process the axis processing trajectories to achieve high performance. Thanks to the computing power of this axis controller that integrates PLC and control panel, it is possible to control complex machines as transfer work centers with simultaneous processing up to 6 independent independent channels such as in robotics and in all areas of industrial automation where high performance and accuracy is required. Thanks to an extensive and powerful set of instructions, the PLC and the successive CNC enable the development of flexible applications for different automation areas. It is possible to connect a maximum of 213 on board I / O. Additional I / O extensions in Ethercat and CanOpen can be added to increase total I / O. It can manage other automation devices that respond to the specifications of CiA 402 (drives) and CiA 406 (encoder and various transducers).

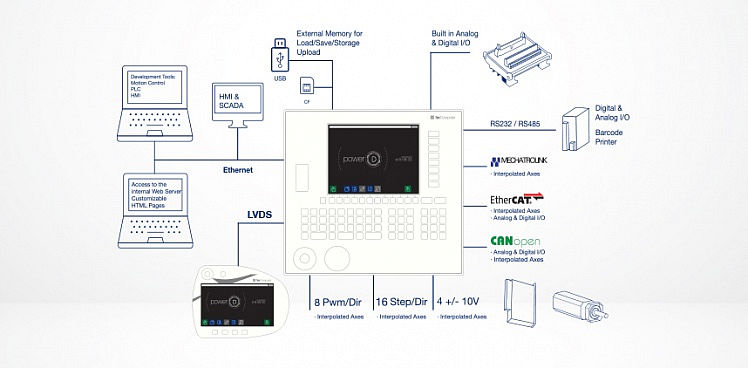

- More...The graphical interface can be customized in the Operator Panel (HMI) section. It is fast because it is connected directly to the controller and is not affected by the delays due to data exchange between the controller and the Operator panel. The connectivity of this powerful controller allows you to manage drives via CANopen, EtherCAT (with CoE profile - CANopen via EtherCAT) and Mechatrolink-II. It is also possible to mix the usual interface techniques in wired logic via analog signals +/- 10V, Step / Direction, PWM / Direction. Axis position feedback can come from the servo drive internal trajectory generator or from incremental and absolute external encoders. A USB port is available on the front panel for storing and uploading data, formulas, application programs and firmware. The system can be updated with backup and restore functions.

Programming is realized using a development tool for PC made by Tex Computer. It enables the development of programs for Motion control, PLC and HMI. An online Debugging tool is also available that allows the developer to check the value of each variable, machine status, insert messages, breakpoints, logical status of the PLC branches and sequential program status, as well as the oscilloscope functions to monitor the movements of the axes. As with all other controllers in the Power family, Power D+ offers a text editor integrated into the operating system (IDE), so the developer can also program in the field without using a PC. - Power D+ Areas of application and machinesMetal, Wood, Stone, Textile, Alimentary, Robotics, Packaging, Delta robot with linear axis kinematics, Delta robot with parallel axis kinematics, Scara robot, Cartesian robot, anthropomorphic robot, Palletizers, Flow Pack packaging , CNC working centers, lathes, wood stamps, printing machines, pantographs, plasma cutting machines, laser cutting machines, waterjet cutting machines, fabric tangent cutting machines, milling up to 5 axes, sheet metal working machines, bridge milling machines, industrial sawing machines, special machines.

- Power D+ Scheme

- Power D+ Technical features

* OptionalStroomvoorziening 24 VDC CPU RISC 32 bit / 264 Mhz, dual-core Flashgeheugen (inclusief het volume F) 24 MB Back-up RAM-geheugen batterij 16 Mb Intern RAM-geheugen (snelle toegang) ** Niet-retentief RAM-geheugen 4/8 MB * Kalender klok Ja USB type 1.1 + 1 type 2.0 Seriële poort 2 RS232 + 1 RS485 Ethernet 10/100 T poort 2 (1 met snelle toegang) Can Bus poort 3 Master EtherCAT poort * Master Mechatrolink-II poort *met INT-Mech. SPI (voor lokale I / O-uitbreiding) 55 uitbreidbaar Lokale PNP digitale ingangen 55 uitbreidbaar Statisch beveiligde digitale uitgangen 24V-1A 32 uitbreidbaar Statische niet-beveiligde digitale uitgangen 24V-60mA ** Maximale lokale digitale I / O 215 (met FDC exp. -Kaart) Analoge ingangen op Hoofdprint 13 met 14 bit resolutie +/- 10V analoge uitgangen van 16bit DAC 8 +/- 10V analoge uitgangen van PWM 8 * op FDC PWM uitgangen 8+ (8 * op FDC) Stap / richting uitgangen 16 verschillende * 5V Push Pull incrementele encoder 8+ (8 * op FDC) 5V Line Driver incrementele encoder 1 (alleen CH A / B) SSI Absolute Encoders 16 * Geïnterpoleerde assen 28 LVDS-interface voor externe panelen (36-pins aansluiting) Ja PID-tijdconsumptie 10 μS / as

** Not available